Automat is with the team having more than decade of experience in design, supply, installation and commissioning, consultation of : 1. Gravimetric 2. Volumetric feeding system, also raw material handling system as per client requirements under turn-key solutions in india as well as abroad.

Weighing system used for level by weight in process industries to maintain the stock and control over it.

Over head cranes are used almost every industries in today’s time. We do provide weighing, data logging, overhead protection to avoid accidental or higher or more than full capacity usage of crane.

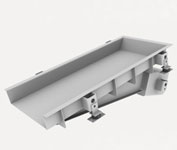

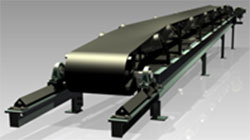

Belt Weigh Feeder is gravimetric devices widely used in steel, cement, other industries for controlled feed rate of the raw material to process on weight to get desired result.

Belt Weigher is gravimetric system mainly used for online material flow measurement conveyed at belt conveyor and show totalized weight to use. It is open loop system that means no control over control feed to the process.

Loss in weigh - LIWS is gravimetric system mainly used for control or loss in material flow measurement with reference of time and show flow rate, totalized weight and material level at weigh bin. It is closed loop system that means having control over material feed to the process.

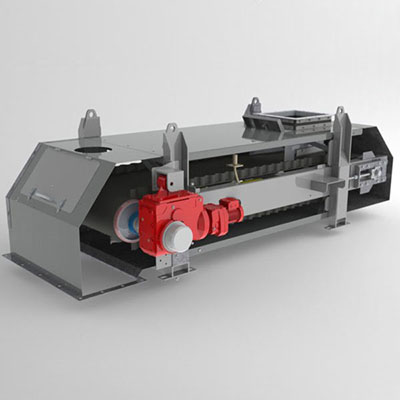

Screw Weigh Feeder - SWF is gravimetric system used to provide controlled material flow with measurement in reference of time and show flow rate, totalized weight. It is closed loop system that means having control over material feed to the process. Mostly used for powder material.

PLCs can be adapted to monitor and control many sensors and actuators; they process electrical signals and use them to carry out preprogrammed commands for almost any application. Supervisory Control and Data Acquisition (SCADA) is a combination of hardware and software used for industrial automation. SCADA allows users to: Supervise and control industrial processes both locally and remotely. Acquire, process, and record data

Almost every segment of industry requires proportional raw material usage for required / desired result in process and record for analysis for improvement in final product. Load cells, Indicators shall be used for weighment, controlled feed and help to maintain record and stock updates.

Automat is one stop customized solutions provider and having reputed well known industrial association, team which can give you quality product, services and support after sale.